For use with Evercoat cream hardener only. Z-GRIP GLAZE® comes packaged with a blue cream hardener. TopcoatĪpply 2K polyester, 2K urethane, 2K epoxy, or 1K primer to manufacturer’s recommendations Final sand with 180 grit followed by 220-320 grit if desired. NOTE: Do not apply over new or uncured coatings. Apply additional layers to build material slightly higher than the surface to allow for sanding to desired contour. Spread a thin layer of mixed material over surface using firm pressure. Approximate setting time is 4 – 5 minutes a temperature of 72☏ (22☌) Application Mix thoroughly until uniform color is achieved. Puddles larger than 4” in diameter will require additional hardener. Measure hardener 2% by weight (add a ribbon of cream hardener from edge to edge across the center of a 4” (10 cm) diameter puddle. Place the desired amount of material on a clean, non-fibrous surface. Use 80-180 grit to remove or scuff the paint and featheredge. Thoroughly dry the surface before repairing. Suitable SubstratesĬlean and degrease the entire panel to be repaired with soap and water, followed by a mild cleaning solvent. Can also be used to fill minor body damage up to 1/8” (3 mm) in depth.

Z-GRIP GLAZE® is a two-part, flowable, polyester finishing putty ideally suited for filling and skim coating body work, pinholes, grind marks, low spots and other surface imperfections.

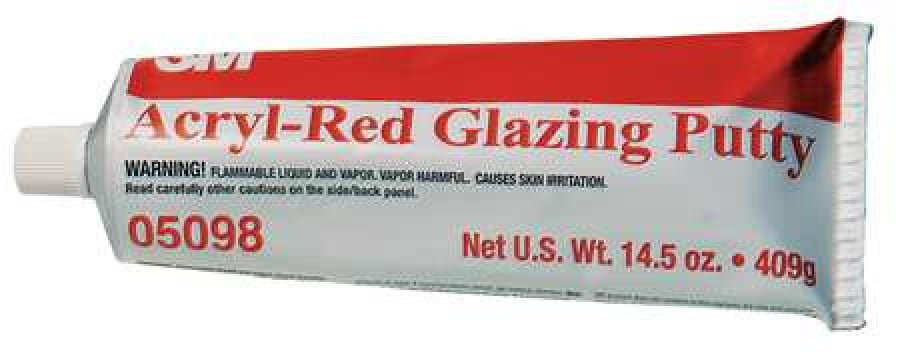

3M GLAZING PUTTY HOW TO

Pumptainer How to Use Evercoat 100482 Z-GRIP GLAZE®

One of the top coating brands in the autobody and collision repair industry, Evercoat, has produced a glaze for its Z-GRIP line. There are certainly a wide variety of brands to choose from. How do I find a good glazing putty to use? Follow manufacturer recommendations for what grit levels of sandpaper to use or whatever standard operating procedures your shop has implemented. In this step you will sand down any high spots and feather the edges of the glaze into the current paint.

3M GLAZING PUTTY FREE

Once the you have completed any or all of the above steps to ensure your surface is smooth and free of imperfections, sand and even out your glaze. This should be your final step before priming.ĭo I need to sand glazing putty before priming? When skim coating, glazing putty may need to be mixed proportianately with your filler as long as the application will result in a very low-build. Yes, glazing putty can and should also be used in skim coating applications and very minor rock chips or dents. In that case, first make a pass applying pressure and then use some of the excess glaze to go back and fill in the low spots. When you are using a glazing putty to fill the low spots you will not need to apply as much pressure, unless of course the low spots also contain pinholes or scratches. Low spots – run the palm of your hand over your sanded body filler to identify any low spots you may have.

Just be sure to spot prime before you paint. Sand scratches – The same technique can also be used for sanding scratches, and in the case that you run into sanding scratches in your primer glazing putty can easily fill those scratches. Pinholes – For pinholes, use a plastic razor blade and apply pressure evenly spreading the glaze across the surface to force it into pinholes.

The most common are pinholes, sanding scratches, and low spots. No matter how good your body work is and how much product technology has improved, you will most likely run into minor surface imperfections at some point. They can be called by a number of names – finishing glaze, finishing putty, glaze, glazing putty – among others. Once mixed, the consistency should be flowable with a decent vertical hang (a.k.a. Most modern glazing putties, or glazes, are two-part, polyester systems intended to be mixed with a hardener. Glazing putty is a finishing putty used for pinholes and other minor surface imperfections.

0 kommentar(er)

0 kommentar(er)